-

Fabrication and

mounting of the bat

fins.

-

Engine Cover and

hinge mounting

-

Complete re wiring

-

Fabrication

of steel windshield

frame

-

Fabrication

and construction of

Convertible

Top

-

Fabrication

of back window

-

Fabrication of Front

Beam support

structure

-

Fabrication

of Gull Wing Doors

-

Constructing

retractable

Headlights

-

Mounting and fitting

of front turn signal

lights

-

Mounting and fitting

of Gas Tank

-

Fabrication and

installation of side

scoops

-

Fabrication

of a 2"body lift

Engine

Cover and

Hinge

Mounting

I wanted

the hinge for the engine

cover to be strong. the

original Bradley GT used

a wood strip fiber

glassed into the back of

the body and wood screws

to mount the hinge. I

used a router to cut a 1

inch wide by 1/4" deep

by 40" long slot in the

back where I was going

to mount the hinge. I

got a piece of

1"x1/8"x40"long steel

strap and glued and

clamped it into the slot

with resin. I then laid

in several layers of

fiberglass and resin

until it was built up

even with the back of

the car. It was then

sanded smooth.

In the

below photos you can see

I bought a piano hinge

cut it to 36" and

drilled 1/8" holes

through the fiberglass

and into the steel strap

to match the holes in

the hinge. I bought 100

5/8" long stainless

steel flat head # 32

allen screws ( from WW

Grainger) as they will be

used in other areas on

the car. I used an #8 32

tap to thread every other

hole on the hinge.

On the

engine cover, I glued a

3/4" 1/8" x 36" long

aluminum strap to the

inside top of the engine

cover itself. I drilled

and tapped through six

of the matching holes

also with an #8-32 tap

and bought six stainless

steel acorn nuts as the

5/8" screws will go

through both the

aluminum and fiberglass

with 1/8" to tighten the

acorn nuts. I used anti-seaze

grease on all the

threads to keep water

from seeping in and

rusting the threaded

holes.

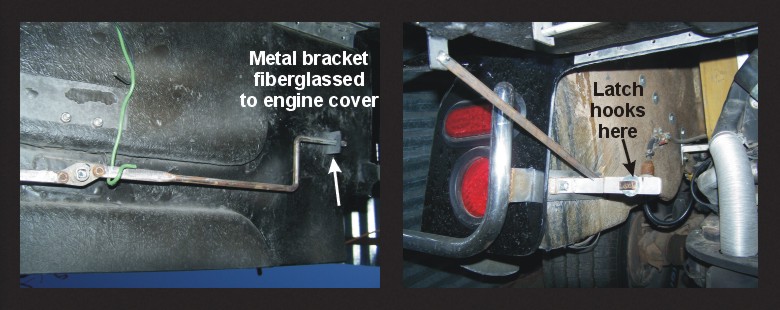

You

can see the mounted

engine cover and how the

hinge is mounted in the

above photos.

Above:

You can see the latch

linkage and the engine

open support rod. I

didn't like the hood pin

latch arrangement so I

borrowed an idea of my

camper shell latch. I

welded tubing to the the

adjustable hood pins and

the rod slides through

the tubing to latch. I

mounted a "T" handle to

the outside center of

the engine cover. It can

be locked if need be.

The green wire goes to

my license plate light

but has not been

connected yet.

|